It is understood that toy manufacturers are mainly concentrated in the two provinces of Zhejiang and Guangdong, so they enjoy a good reputation in the country as a toy capital. Most electronic toys need to be locked with certain screws, and the characteristics of toys such as toys are very irregular in appearance, the cycle is not very long, and the replacement is fast. Therefore, there are few products that meet the requirements of fully automated production. At present, the majority of them are manually locked.

Taking into account the above factors, we recommend that manufacturers use hand-held automatic screw-locking machines, which can save assembly time, without the need to take the screws, the feeding system directly transfers to the electric screwdriver, and the button is pressed to complete the payment. In addition, for the versatility of the screw machine, it is recommended that when designing toys, the screws should be specified within several specifications. Workers reduce the replacement of screws when they replace products and save time.

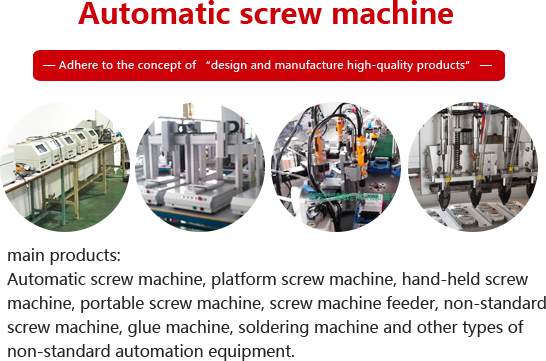

Hand-held automatic lock screw machine is more suitable for irregular toys, but if the output is stable, the product has more screws and uniform specifications, it is also a good choice to use a multi-axis screw machine.